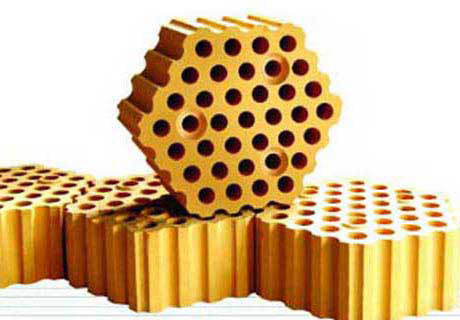

Properties And Uses Of High Alumina Bricks

High alumina brick is a kind of refractory material, and the main component of this refractory material brick is Al2O3. It is a neutral refractory material with an alumina content of more than 48%. It is formed and calcined from bauxite or other raw materials with high alumina content. High thermal stability, refractoriness above 1770°C. It has good slag resistance and is used for the lining of masonry steelmaking electric furnaces, glass melting furnaces, and cement rotary furnaces.

a. Refractoriness

The refractoriness of high-alumina bricks is higher than that of clay bricks and semi-silica bricks, reaching 1750~1790°C, which is a high-grade refractory material.

b. Load softening temperature

Because the Al2O3 in high alumina products is high, the amount of impurities is small, and the formation of fusible glass is less, the softening temperature under load is higher than that of clay bricks, but because the mullite crystallization does not form a network structure, the softening temperature under load is still not as high as that of silica bricks.

c. Slag resistance

There are more Al2O3 in high alumina bricks, which are close to neutral refractory materials, and can resist the erosion of acid slag and alkaline slag. Because it contains SiO2, the ability to resist alkaline slag is weaker than that of acid slag.

The use of high alumina brick

It is mainly used for masonry lining of blast furnaces, hot blast stoves, electric furnace roofs, blast furnaces, reverberatory furnaces, and rotary kilns. In addition, high alumina bricks are also widely used as open-hearth regenerative checker bricks, plugs for pouring systems, nozzle bricks, etc. However, the price of high alumina bricks is higher than that of clay bricks, so it is not necessary to use high alumina bricks where clay bricks can meet the requirements.