Brief Introduction

High Alumina Refractory Balls are made of industrial alumina and refractory kaolin as the main raw materials, which are made by scientific formula, forming and hightemperature calcination.

Refractory alumina ball is divided into ordinary refractory ball and high aluminum resistance ball. Refractory porcelain ball high temperature resistance to high temperature can reach 1900 degrees, high mechanical strength and long-term use.

Technical Datas

| Item | High alumina | Low creep | Mullite | Corundum |

| Size(mm) | 40-80 | 40-80 | 40-80 | 40-80 |

| AL2O3(%) | 65 | 70 | 75 | 95 |

| Refractoriness under load(°C) | 1450 | 1460 | 1530 | 1650 |

| Apparent Porosity(%) | 25 | 23 | 22 | 18 |

| Bulk Density(g/cm3) | 2.3 | 2.4 | 2.5 | 3.1 |

| Cold crushing strength(Mpa) | 13 | 14 | 32 | 36 |

| Thermal shock resistance (1100°Cwater cooling) cycle ≥ |

15 | 10 | 20 | 7 |

| Refractoriness(°C) | 1710 | 1750 | 1800 | 1800 |

Features

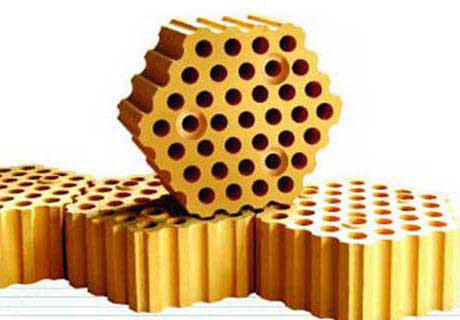

1. good chemical stability, no chemical reaction with the material;

2. high mechanical strength, long use cycle;

3. good thermal stability, high strength;

4. high temperature resistant performance, the highest heat resistant ceramic ball temperature can reach 1900 degrees;

Application

High alumina refractory balls are mainly stacked in industrial furnaces to achieve heat storage. It can be used in industrial kilns such as blast furnace ironmaking hot blast stove, high and low temperature converter furnace in fertilizer plant, reformer, hydrogenation converter, desulfurization tank and methanation furnace.