Brief Introduction

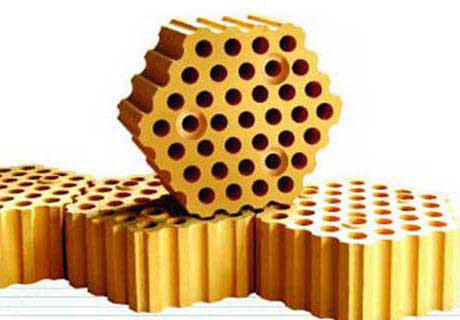

The anchor brick uses Al2O3 as the main raw material, and is a top structure supported by the force between the metal pendant and the steel bar. Furnace roof refractory bricks. Anchor bricks have good high-temperature firing performance, high thermal shock resistance, and strong peeling resistance. We have good quality lightweight anchor fire bricks for sale at low prices, standard size fire anchor brick specifications and categories are available as well as competitive prices and high-grade high-quality fire anchor brick products, other specifications and sizes of fire anchor anchor bricks are available as per customer requirements , welcome to contact us or email us for a free quotation or price list.

Technical Datas

| Item |

Anchor Brick | |||

| LZ-55A | LZ-55B | LM-75A | LM-75B | |

| Al2o3 | 55.0 | 55.0 | 75.0 | 75.0 |

| Cao | 2.0 | 2.0 | 2.0 | 2.0 |

| Cold Crushing Strength | 50 | 50 | 55 | 55 |

| 0.2Mpa Refractoriness Under Load | 1450 | 1450 | 1550 | 1550 |

| Apparently Porosity | 22 | 24 | 21 | 23 |

| Bulk Density | 2.30 | 2.30 | 2.60 | 2.60 |

Features

1. high strength;

2. strong peeling resistance;

3. good thermal shock resistance;

Application

Anchor brick is a new type of roof structure for anchoring bricks for industrial furnaces. The top of the furnace is a roof structure supported by metal hanging fire bricks and refractory bricks. Therefore, leakage of reactive gas and hot gas in the furnace may damage the metal hanging parts, thereby causing a collapse of the top of the furnace. Industrial kiln and flue wall are composed of inner lining, heat insulation layer and outer wall layer, the inner lining is refractory brick, the outer wall is made of ordinary sintered brick. Anchorage is required between these layers, the tensile strength of the anchor refractory brick is obviously improved, the stress generated at the groove is blocked at the rib and cannot be transmitted continuously. Therefore, the anchor brick of this structure is not easy to break.